Calibration

Devices and software for accurate machine tool and CMM set-up create a foundation for high quality, repeatable, efficient manufacturing processes. Learn More

Tool setting and broken tool detection

Contact and non-contact tool setting systems to detect and adjust to the condition or wear of cutting tools.Learn More

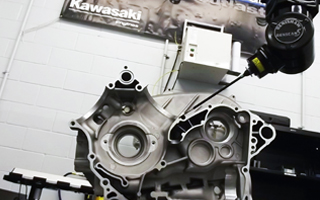

On-machine probing

Machine tool probes ensure that parts are set correctly, check for changes like thermal drift during machining and assure parts meet their specification and design intent.Learn More

Gauging

Our Equator™ gauging system offers precise and rapid gauging of even complex parts, tracking trends in machining and enabling automatic process adjustments to account for changing variables like thermal drift.Learn More

Inspection

Our 5-axis CMM probing systems can measure parts to inspect form and surface finish, ensuring the performance of sealing surfaces and the efficiency of vehicles. They provide rapid data collection for high precision components like engine blocks and cylinder heads.Learn More

Position encoders

Magnetic, interferometric laser and optical position encoders give high accuracy position and motion control over long distances or in tight spaces.Learn More

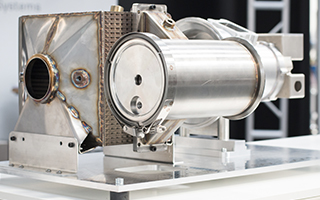

Additive manufacturing

Metal 3D printing using a range of metal powders to create strong, light components – like lattice work and internal bracing for structures.Learn More

Raman spectroscopy

For checking the material make-up of paints, specialist materials and the quality of surface coatings.Learn More