Machine tool probing and on-machine tool measurement is an established best practice in the machining industry. Manually setting and inspecting tools and parts can be detrimental to machining performance and profitability. Our probing and tool setting systems help manufacturers to reduce scrap rates, eliminate machine down-time, and improve component quality.

Our solutions enable automated component set-up, in-cycle gauging, tool setting, and broken tool detection. When coupled with automatic offset updates, our technology enables you to machine with confidence, reduce set‑up times, and improve process control.

What is machine tool probing and tool measurement?

Machine tool probing and tool measurement is the process of measuring the position, dimensions, and features of a workpiece or cutting tool on a machine tool. This ensures you meet required specifications and tolerances before and during the machining process.

Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors.

Machine tool probes for workpiece setting and inspection gather data on the shape, size, and position of a workpiece. Use to accurately measure features of machined parts and provide fast part set-up.

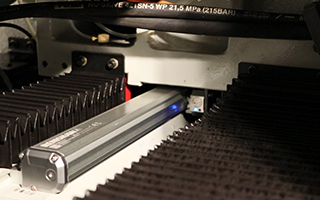

Tool setting and broken tool detection systems measure the cutting tool itself, rather than the workpiece. They establish a reference point on the cutting tool and check for any wear or breakage.

The benefits of machine tool probing and tool measurement

Workpiece and tool measurement can happen before, during, and after machining tasks. By practicing this type of measurement, eliminate costly machine downtime and component scrapping. This allows you to better invest your time and money into productive machining.

Increase throughput from existing assets defer capital expenditure, reduce subcontract and overtime bills, and pursue additional business.

Increase automation in setting and measurement processes reduce human intervention and redeploy staff into proactive engineering roles. Give your machine tools the intelligence they need to make decisions for themselves, enabling extended periods of ‘lights out machining.

Eliminate rework and scrap probing a workpiece at key stages of the machining process allows process parameters adjustments. This reduces part-to-part variation, thus increasing process capability and reducing non-conformance. Helping you to lower unit costs and shorten lead times.

Keep pace with the needs of your market automated setting using probes will allow you to set up complex components, eliminating the need for costly precision fixtures. This means you can respond quickly to new customer requirements by rapidly introducing new processes.